I think they have designed this to create maximum internet forum column inches.

-

WANTED: Happy members who like to discuss audio and other topics related to our interest. Desire to learn and share knowledge of science required. There are many reviews of audio hardware and expert members to help answer your questions. Click here to have your audio equipment measured for free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Schitt Sol Turntable

- Thread starter garbulky

- Start date

watchnerd

Grand Contributor

You need basic engineering quality for a TT. A unipivot arm is a way of side-stepping the need for high-precision (low friction but zero play) bearings but there's no similar option for the main platter bearing. You must have high quality there if you want to avoid rumble, rocking, and all the rest.

Right, which is why I'm skeptical about what the rumble / SNR & wow & flutter will be for the Sol.

watchnerd

Grand Contributor

I think they have designed this to create maximum internet forum column inches.

It's the NOS R2R DAC of turntables.

AudioSceptic

Major Contributor

Yes, as did pretty much everything else at the time. The Valhalla board brought in a quartz-derived supply for the synchronous motor in 1982. It was still single speed, but it was the *LP*12. Singles were things you stacked on an autochanger.Even the basic Linn LP12 had a synchronous motor for a very long time. Don't know how it is today (EDIT: it is, the Majic PS still requires a pully to change the speed)

Edit: the Majik PS seems to be a modern version of the Valhalla, so you get quartz-generated speed accuracy for the motor, but still single speed. I'd have thought they could've easily built in a speed option but there you are. Can't put too much in the basic model as you need to leave a gap between it and the next one up.

Last edited:

I don't understand what 3 mounting holes have to do with it?

Usually you have 2 slots on a standard mount arm and two holes on a standard mount cartridge, which gives you freedom to move the cartridge screws in each slot before tightening them down. 3 matching holes on the arm and cartridge nail down the alignment.

There are a lot of "ready to run" TTs that come either with a fixed headshell and a pre-installed cart, or a removable headshell with pre-installed cart, usually something from the Ortofon 2M series or the lower end of the AT range.

Do you have the name of a vendor that pre-installs a cart in a headshell? Sounds like the thing for friends that ask about this stuff.

AudioSceptic

Major Contributor

Linn have long used 3-bolt mounting for their top arm and MCs, from the Ekos/Troika onwards.Are we talking about p-mount cartridges and arms? I'm not familiar with any of those. Or are there other arms and other cartridges with 3 mounting holes like the Regas?

Aside: am I the only person who thinks it's insane that there is still no standard for arm/cartridge mounting and geometry, so that any cartridge fixes precisely with 3, not 2, bolts*, guaranteeing correct offset and overhang? Getting that wrong results in a lot of extra distortion but you have to wiggle the cartridge about by eye and fix it with 2 bolts with no positive locking in position.

*Should these be called machine screws?

Last edited:

watchnerd

Grand Contributor

Usually you have 2 slots on a standard mount arm and two holes on a standard mount cartridge, which gives you freedom to move the cartridge in each slot before tightening it down. 3 matching holes on the arm and cartridge nail down the alignment.

Do you have the name of a vendor that pre-installs a cart in a headshell? Sounds like the thing for friends that ask about this stuff.

Well, 3 matching holes will only match 1 alignment....and it may not be the alignment I want. But I like maximum configuration options. Many don't.

LPGear sells carts pre-mounted in headshells, either as a pre-made package, or you can pick a cart, pick a headshell, and for $10 they'll mount it.

Depending on your arm, you may still need to adjust HTA / overhang. But at least you don't have to muck with teeny wires and screws.

Personally, I like the line of Japan-only AT headshells that come in a variety of weights (13g, 15g, 18g) , have pre-drilled screw holes, and allow for azimuth and HTA adjustment at the headshell.

watchnerd

Grand Contributor

Aside: am I the only person who thinks it's insane that there is still no standard for arm/cartridge mounting and geometry

Which geometry are you going to force on me?

And what if it's not what I like to optimize for?

AudioSceptic

Major Contributor

I think the theory is that you want low torque so that minimal vibration gets to the platter but you need a heavy platter for speed stability which needs a lot of torque to overcome stiction and inertia so a nudge is what's required to fill the gap. The alternative is electronic control which starts with high torque and then automatically ramps it down as the required speed is reached.All the nottingham analogue decks required a push to get going, the AC motor cannot spin up the heavy platters. I've liked the sound of all the nottingham analogue decks I've heard.

AudioSceptic

Major Contributor

They "might* have sourced good parts where they matter but until we see the measurements we can only guess.Right, which is why I'm skeptical about what the rumble / SNR & wow & flutter will be for the Sol.

AudioSceptic

Major Contributor

I think in the UK any dealer will do that for you when you buy the TT or cart (maybe a nominal charge for the latter if's a budget one).Do you have the name of a vendor that pre-installs a cart in a headshell? Sounds like the thing for friends that ask about this stuff.

AudioSceptic

Major Contributor

How many are there, and how do you optimise?Which geometry are you going to force on me?

And what if it's not what I like to optimize for?

I've thought the same, but getting things wrong seems to be part of the appeal of vinyl to many.Aside: am I the only person who thinks it's insane that there is still no standard for arm/cartridge mounting and geometry, so that any cartridge fixes precisely with 3, not 2, bolts*, guaranteeing correct offset and overhang?

watchnerd

Grand Contributor

How many are there, and how do you optimise?

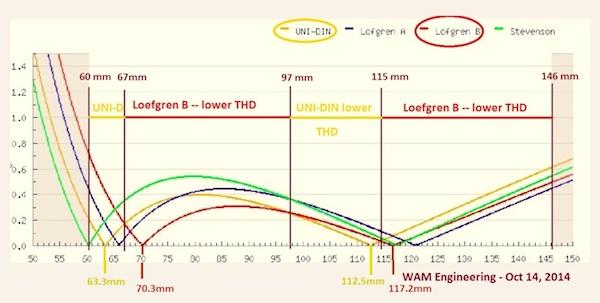

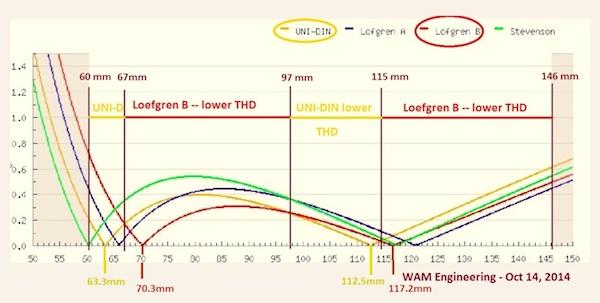

Universal ones (i.e. not vendor-specific):

Baerwold / Lofgren A

Lofgren B

Stevenson

UNI-DIN

Vendor-specific:

Technics

probably some others I don't know

How does one optimize?

Pick where on the LP you want the most distortion vs least distortion. Or try to pick lowest average distortion. There is no right answer.

This is often related to the music genre, i.e. Classical often ends sides with big crescendos and complex passages, leading one to pick alignments that have the least end-of-side distortion. But for other genres, you may not want that.

Last edited:

watchnerd

Grand Contributor

I've thought the same, but getting things wrong seems to be part of the appeal of vinyl to many.

Which version of 'right', in terms of an alignment, are you going to standardize on?

They're all imperfect compromises.

I'd go for one chosen by experts who should be involved in defining the international standard, if such a thing was going to happen. If such a thing was done decades ago then part of the circle of confusion in mastering and playback would be sort of controlled by now.Which version of 'right', in terms of an alignment, are you going to standardize on?

They're all imperfect compromises.

watchnerd

Grand Contributor

I'd go for one chosen by experts who should be involved in defining the international standard, if such a thing was going to happen. If such a thing was done decades ago then part of the circle of confusion in mastering and playback would be sort of controlled by now.

The experts have been debating this since the 1930s.

See Tonearm Geometry Analysis by Graeme Dennis (c) 1983, 2018 -- 217 pages. [You'll need a VinylEngine login to get this]

The last attempt to create a new standard, the UNI-DIN alignment, hasn't been adopted by any major TT maker that I know of. It's one of the "selling points" of the pricey SMARTractor.

The Japanese TT / arm makers tend towards Stevenson-like alignments (although the new Jelco arms are Baerwald), while European makers tend to shy away from Stevenson.

Personally, I use 2 different alignments, depending on whether I'm listening to 33 RPM or 45 RPM LPs, because the 45 RPM LPs have more deadwax, which necessitates different compromises.

- Joined

- Oct 11, 2018

- Messages

- 3,741

- Likes

- 6,464

A unipivot bearing allows the arm to rotate this way and that around the pivot axis, which has to cause a commensurate (and unwanted) stylus rotation within the groove. The most successful unipivots seemed to have been oil damped (silicon gunk), such as the Audiocraft, Formula 4, Kieth Monks (which used a mercury bath), and a few others.You need basic engineering quality for a TT. A unipivot arm is a way of side-stepping the need for high-precision (low friction but zero play) bearings...

Unipivots often have the advantage of quick armtube removal and replacement, but at what cost and tradeoff? Compare the engineering behind this, along with fit and finish, with something like the old Technics EPA 500 system, or the Micro 505 system (which allowed tonearm tube change), and laugh. I don't mean laugh at it (although you could), but laugh at it because it's cheap and will probably be fun, for a new user. It's the perfect Schiitt product.

You are correct in that the tonearm design is simply an inexpensive price point thing. But so is the entire deck. It looks cheaply built overall (except the carbon fiber armtube, which is impressive), lightweight, and you have to wonder how long it will last, in home use? Reviewers will likely praise it for its slam, pace and timing. Or maybe they will just say it's a cheap compromise at a price point. We'll see.

AudioSceptic

Major Contributor

Yes, indeed, and that's my point. Are you going to measure the inner and outer track radii of each record, factor in genre, and then realign the cartridge each time? Or even, if you have a "classical" session one day and a "rock" session on another, change it each time? And this bearing in mind the inherent distortion, inaccuracy of internal cartridge build, dust on records, dirt on stylus, etc.?Universal ones (i.e. not vendor-specific):

Baerwold

Lofgren

Stevenson

UNI-DIN

Vendor-specific:

Technics

probably some others I don't know

How does one optimize?

Pick where on the LP you want the most distortion vs least distortion. Or try to pick lowest average distortion. There is no right answer.

This is often related to the music genre, i.e. Classical often ends sides with big crescendos and complex passages, leading one to pick alignments that have the least end-of-side distortion. But for other genres, you may not want that.

Anyway, Rega and Linn have decided what works for most, while still allowing dissenters to use only 2-hole mounting if they insist, or for carts with only that option. SME have a different take, using holes not slots and a sliding bed-plate, a system with its own alignment issues. I just think the free-for-all we've always had with vinyl has been the cause of far more alignment errors than any standardised geometry would've been.

The very fact that this contraption elicited so far 79 posts is proof that Schitt knows marketing.

If one needs a much better TT , for less than at the asking price, go to e-Bay and get a Japanese DD circa 75~85 ..

e.g

Denon DP-57L

If one needs a much better TT , for less than at the asking price, go to e-Bay and get a Japanese DD circa 75~85 ..

e.g

Denon DP-57L

Similar threads

- Replies

- 7

- Views

- 361

- Replies

- 5

- Views

- 640